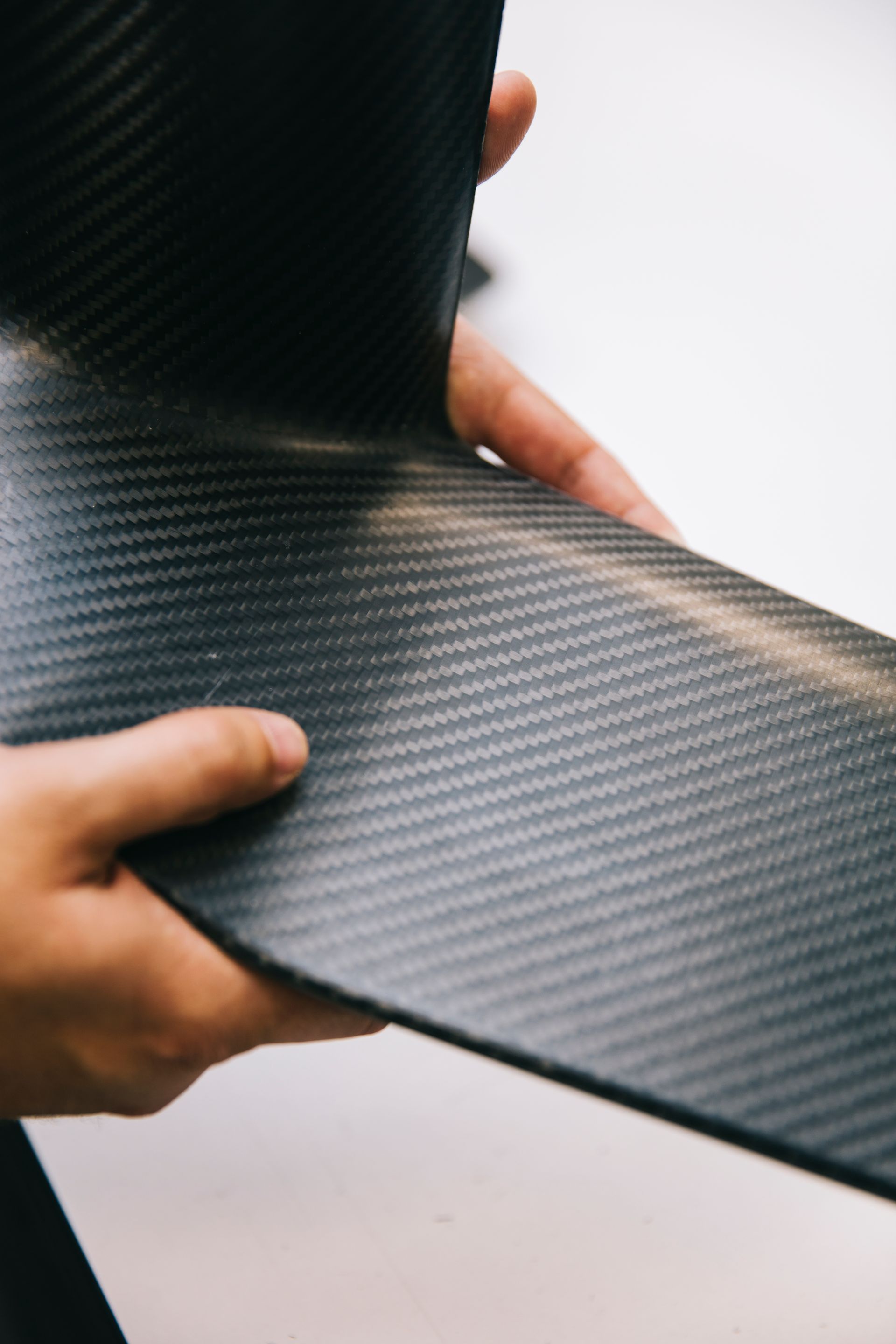

How Advanced Materials (Aluminum Carbon Fiber) Impact Collision Repairs

How Aluminum Changes

Collision Repairs

Aluminum behaves very differently than steel during a collision. It doesn’t bend the same way, and once it’s damaged, it often can’t be reshaped safely.

This means:

- Aluminum parts may need full replacement instead of repair

- Repairs require isolated work areas to avoid contamination from steel dust

- Special tools and trained technicians are necessary

If aluminum repairs aren’t done correctly, the vehicle’s structural integrity and safety can be compromised. That’s why not every shop is equipped to handle these repairs properly.

Why Advanced Materials Affect Repair Costs and Timelines

Because aluminum and carbon fiber repairs demand special tools, training, and parts, they often increase both repair costs and timelines.

Insurance companies may question these costs, especially if they’re unfamiliar with the requirements. This is where expert oversight matters—cutting corners on advanced materials can lead to unsafe repairs and future issues.

Why This Matters for Safety and Value

Improper repairs to aluminum or carbon fiber can affect crash performance, void warranties, and reduce resale value. For attorneys, this can weaken property damage claims. For vehicle owners, it can put safety at risk. Choosing a collision repair partner who understands advanced materials isn’t optional—it’s essential.

As vehicles continue to evolve, collision repairs must evolve with them. Aluminum and carbon fiber offer major benefits, but only when repaired using the right methods and expertise. At VICE, we make sure advanced materials are treated with the care they demand. From insurance negotiations to final inspections, we protect your vehicle, your safety, and your peace of mind—every step of the way.